I see where the confusion is coming from — it seems you're mixing up the

working load limit and the

tensile strength (or

breaking strength).

Working Load Limit (WLL): The weight that the rope can safely hold. The working load is about 15–25% of the tensile strength, or in other words, the rope's tensile strength is about 4x–7x the working load limit. As

@JesiBel wrote, working load limit already takes into account the daily wear, knots, and environmental conditions. If the working load is around your body weight or higher, the rope is fine.

If OP's rope has a WLL of 139 pounds, its tensile strength is somewhere between 550 and 970 pounds. There is no way that a 3/8-inch poly rope has a tensile strength of only about 140 pounds. It seems that OP's rope is strong enough.

Tensile Strength: The force at which the rope is expected to actually break under laboratory conditions. It's usually 4x–7x the working load limit. If the working load limit is not specified for a rope, but only the tensile strength, you need to divide it by 7

(to be on the safe side, divide by 7, not by 4), and the number you get should be equal to or higher than your body weight.

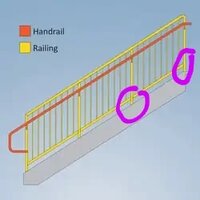

Regarding anchor points: You can use either. That's a metal railing, screwed onto a metal frame, and by the look of it, the place was built according to serious safety standards. To be blunt, there's no fucking way it's going to break. In my opinion, you can tie the rope on it literally anywhere.

However, be careful you don't knock off the fire extinguisher (red pipe). That thing works by breaking when exposed to heat if there's a fire, and its end can very easily be knocked off by accident if you're not careful. If that happens, water will start pouring out, and people will likely come to investigate.

And yes, I wouldn't use a rolling chair. It's unstable and not safe.